Tungsten carbide powder is a fine powder composed of tungsten (W) and carbon (C) atoms. It is known for its exceptional hardness and wear resistance and is widely used in various industrial applications, particularly in producing cutting tools, drilling bits, wear-resistant parts, and abrasion-resistant coatings.

Appearance: dark to light grey with increased particle sizes, without obvious foreign matters.

Composition: Tungsten carbide (WC) consists of equal parts tungsten and carbon atoms. This composition gives it its remarkable hardness and other desirable properties.

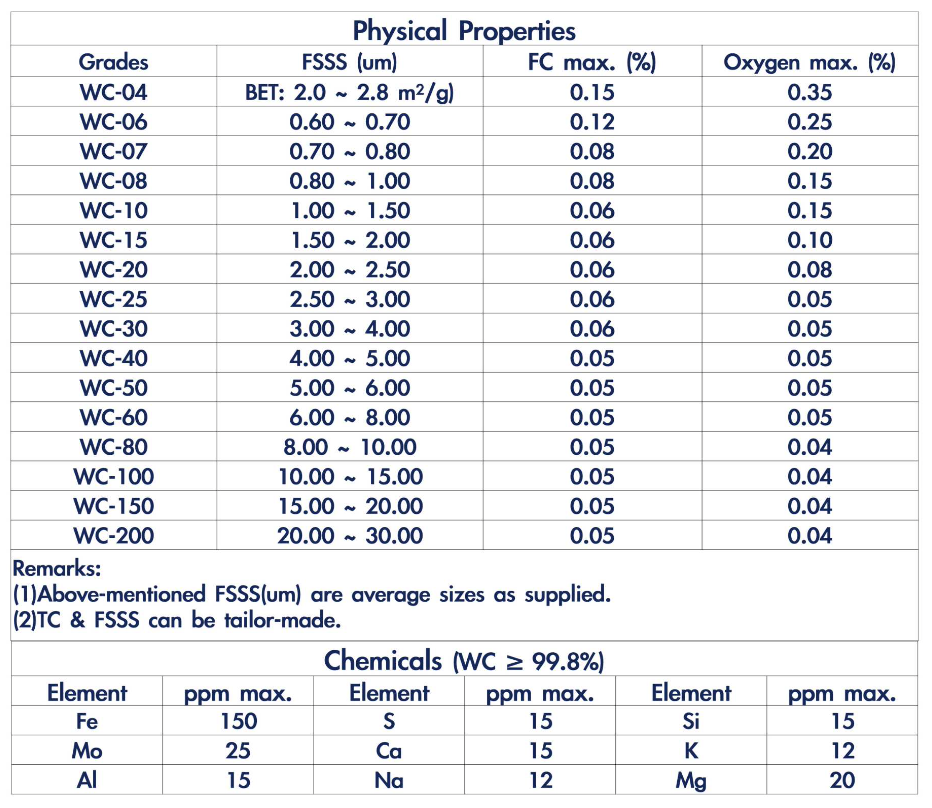

Particle sizes: 0.4-30um. High purity, concentrated particle size distribution, optimized crystal forms and consistent quality.

Production: In a controlled environment, tungsten carbide powder is produced through a high-temperature reaction between tungsten metal and carbon black (or another carbon source). The process typically involves heating tungsten and carbon sources to temperatures exceeding 1300-2200 degrees Celsius in the presence of a reducing agent.

Properties:

- Hardness: Tungsten carbide is one of the hardest materials known, second only to diamond. This hardness makes it highly resistant to wear and abrasion.

- High Melting Point: It has an extremely high melting point, exceeding 2,870 degrees Celsius (5,198 degrees Fahrenheit).

- Toughness: While tungsten carbide is extremely hard, it is also relatively brittle. It is often combined with a metallic binder phase, such as cobalt (Co), to produce cemented carbides (hard metal alloys) to improve toughness.

Applications: Tungsten carbide powder is used in a wide range of applications, including:

- Cutting Tools: It is a key material for producing cutting inserts, drills, end mills, and saw blades used in machining and metalworking.

- Wear Parts: Tungsten carbide makes wear-resistant components like nozzles, valves, and pump parts in industries such as oil and gas, mining, and manufacturing.

- Abrasion-Resistant Coatings: It creates coatings that protect surfaces from wear and erosion.

- Mining and Drilling: Tungsten carbide buttons are employed in manufacturing rock drilling bits used in mining, construction, and exploration drilling.

Tungsten carbide powder is a valuable material in industries where high wear resistance and cutting performance are essential. Its versatility and durability make it a critical component in many industrial processes and applications.

Sieving and Packaging:

(1) Sieving as per GB/T 4295-2008;

(2) Iron drum with inner double vacuum-sealed plastic bags and net weight of 50kgs.