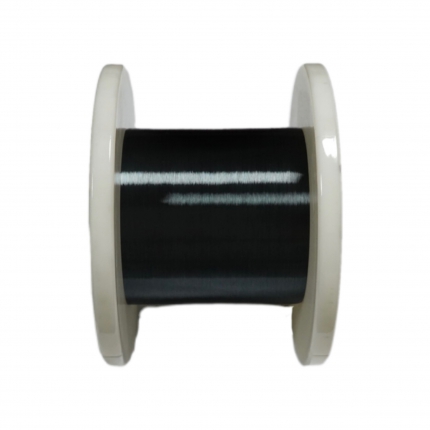

Potassium-Doped Tungsten Wire is manufactured using pure tungsten metal combined with trace amounts of potassium to enhance its high-temperature performance. This wire is produced through powder metallurgy and plastic processing methods, including wire drawing, electrolytic polishing, and other techniques.

Key Features:

1. High Melting Point: Capable of withstanding extreme temperatures without deformation or melting.

2. High Strength and Durability: Offers excellent mechanical strength and longevity, especially at high temperatures.

3. Low Evaporation Rate: Reduces vaporization even in high-temperature environments, which extends the wire's useful life.

4. Corrosion Resistance: Provides resistance to acids, alkalis, and other corrosive substances.

5. Creep Resistance: Enhanced by potassium doping, the wire can resist sagging or deformation, even at very high temperatures.

Applications:

1. Lighting Industry: Used primarily in incandescent and halogen lamps as filament material due to its excellent durability and stable performance under high heat.

2. Electron Tubes and Vacuum Devices: Its low evaporation and high melting point make it ideal for use in high-temperature vacuum environments.

3. High-Temperature Heating Elements: Frequently used in various heating elements and furnace applications due to its excellent thermal properties.

Physical properties:

(1)Diameter: 15um min. Diameter tolerance, winding property, tensile strength, straightness, and high-temperature properties as per GT/B4181-2017.

(2)Surface properties: Smooth surface without mould spots, cracks, burr, pit or groove. The dark wire appears evenly black with light blue permitted, and the white wire appears silver white or silver grey.